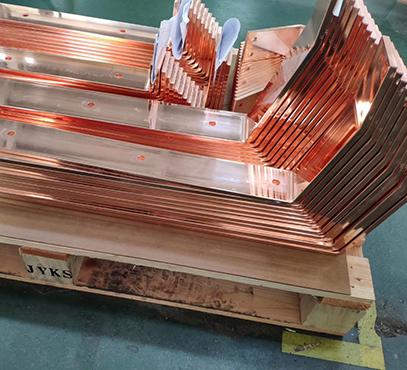

Makina Opangira Mafakitale a Hydraulic Copper Busbar Pinding Machine

Cholinga chathu ndi kumvetsetsa kuwonongeka kwa khalidwe ndi zomwe zatulutsidwa ndikupereka chithandizo chabwino kwambiri kwa ogula akunyumba ndi akunja ndi mtima wonse pa Factory Outlets Hydraulic Copper Busbar Bending Machine, Ngati mukufuna katundu aliyense, kumbukirani kuti mukhale omasuka kuti mutitumizire imelo yoyenera kapena tidzakuyankhani mkati mwa maola 24 okha ndipo mtengo wabwino kwambiri udzaperekedwa.

Cholinga chathu ndi kumvetsetsa kuwonongeka kwa khalidwe ndi zotsatira zake ndikupereka chithandizo chabwino kwambiri kwa ogula am'deralo ndi akunja ndi mtima wonse.Makina Opindira Mabasi a Press Brake ndi Copper Busbar, Zogulitsa zathu ndi mayankho athu zimatumizidwa kunja padziko lonse lapansi. Makasitomala athu nthawi zonse amakhutira ndi khalidwe lathu lodalirika, ntchito zathu zodalirika kwa makasitomala komanso mitengo yopikisana. Cholinga chathu ndi "kupitiriza kupeza kukhulupirika kwanu mwa kupereka khama lathu pakukonza zinthu ndi ntchito zathu nthawi zonse kuti titsimikizire kuti ogwiritsa ntchito athu, makasitomala, antchito, ogulitsa ndi madera apadziko lonse lapansi omwe timagwirizana nawo akukhutitsidwa".

Tsatanetsatane wa Zamalonda

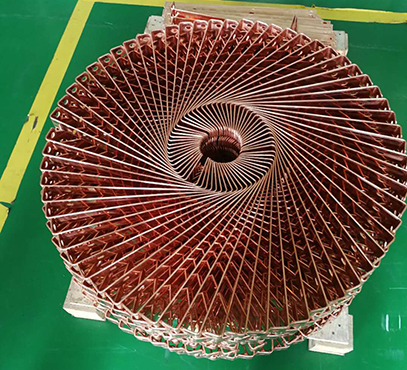

Mndandanda wa GJCNC-BB wapangidwa kuti upinde busbar workpiece bwino komanso molondola

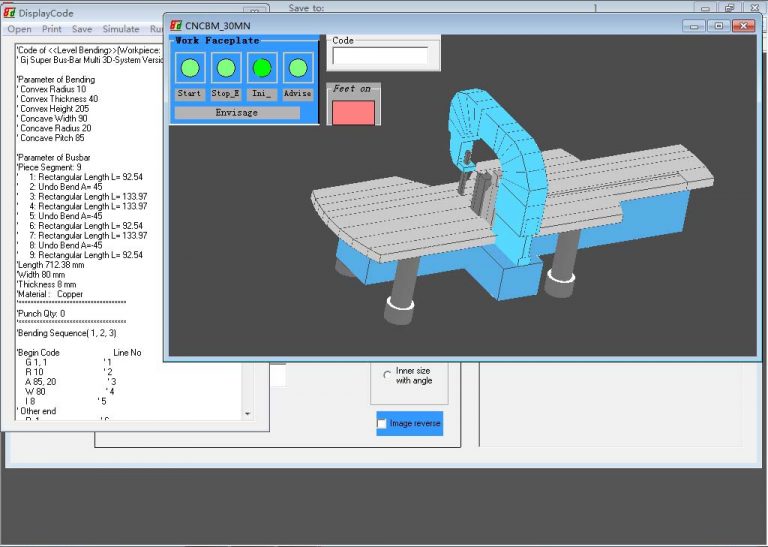

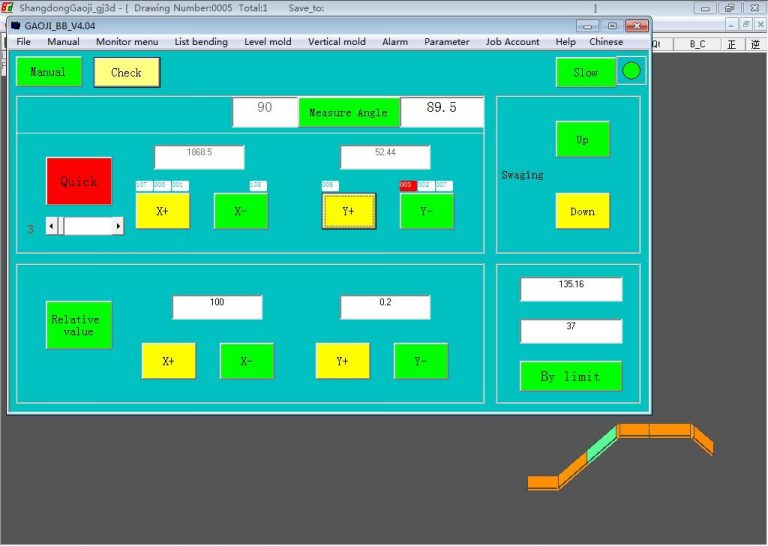

CNC Busbar Bender ndi zida zapadera zogwiritsira ntchito makina opindika a busbar zomwe zimayendetsedwa ndi kompyuta, Kudzera mu X-axis ndi Y-axis coordination, kudyetsa pamanja, makinawo amatha kumaliza mitundu yosiyanasiyana ya zochita zopindika monga kupindika molunjika, kupindika molunjika kudzera mu kusankha mitundu yosiyanasiyana ya ma die. Makinawo amatha kufanana ndi pulogalamu ya GJ3D, yomwe imatha kuwerengera molondola kutalika kwa kupindika. Pulogalamuyo imatha kupeza yokha njira yopindika ya workpiece yomwe imafuna kupindika kangapo ndipo pulogalamu yodziyimira yokha imachitika.

Munthu Wamkulu

Makhalidwe a GJCNC-BB-30-2.0

Makinawa amagwiritsa ntchito kapangidwe kapadera kopindika kotsekedwa, ali ndi katundu wapamwamba kwambiri wa kupindika kotsekedwa, komanso ali ndi mwayi wopindika kotseguka.

Chipinda Chopindika (Y-axis) chili ndi ntchito yolipirira zolakwika za ngodya, kulondola kwake kopindika kumatha kukwaniritsa muyezo wapamwamba wa magwiridwe antchito. ± 01°.

Ikakhala yopindika molunjika, makinawo ali ndi ntchito yolumikiza ndi kumasula yokha, mphamvu yogwiritsira ntchito imawonjezeka kwambiri poyerekeza ndi kulumikiza ndi kumasula ndi manja.

Mapulogalamu a GJ3D Programming

Kuti tigwiritse ntchito makina olembera okha, mosavuta komanso mosavuta, timapanga ndikupanga pulogalamu yapadera yopangira GJ3D. Pulogalamuyi imatha kuwerengera yokha tsiku lililonse mkati mwa kukonza mabasi, kuti ipewe kutaya zinthu chifukwa cha zolakwika pakulemba ma code pamanja; ndipo pamene kampani yoyamba ikugwiritsa ntchito ukadaulo wa 3D mumakampani opangira mabasi, pulogalamuyi ikhoza kuwonetsa njira yonse ndi mtundu wa 3D womwe ndi womveka bwino komanso wothandiza kuposa kale lonse.

Ngati mukufuna kusintha zambiri za kukhazikitsa kwa chipangizocho kapena magawo oyambira a die. Muthanso kuyika tsiku ndi chipangizochi.

Zenera logwira

Mawonekedwe a kompyuta ndi anthu, ntchitoyi ndi yosavuta ndipo imatha kuwonetsa momwe pulogalamuyo imagwirira ntchito nthawi yomweyo, chinsalucho chimatha kuwonetsa zambiri za alamu ya makinawo; imatha kukhazikitsa magawo oyambira a die ndikuwongolera momwe makinawo amagwirira ntchito.

Dongosolo Logwira Ntchito Mothamanga Kwambiri

Kutumiza kwa screw ya mpira molondola kwambiri, kogwirizana ndi chitsogozo cholunjika cholondola kwambiri, kulondola kwambiri, kugwira ntchito mwachangu, kugwira ntchito nthawi yayitali komanso popanda phokoso.

Chogwirira ntchito

Cholinga chathu ndi kumvetsetsa kuwonongeka kwa khalidwe ndi zomwe zatulutsidwa ndikupereka chithandizo chabwino kwambiri kwa ogula akunyumba ndi akunja ndi mtima wonse pa Factory Outlets Hydraulic Copper Busbar Bending Machine, Ngati mukufuna katundu aliyense, kumbukirani kuti mukhale omasuka kuti mutitumizire imelo yoyenera kapena tidzakuyankhani mkati mwa maola 24 okha ndipo mtengo wabwino kwambiri udzaperekedwa.

Malo Ogulitsira MafakitaleMakina Opindira Mabasi a Press Brake ndi Copper Busbar, Zogulitsa zathu ndi mayankho athu zimatumizidwa kunja padziko lonse lapansi. Makasitomala athu nthawi zonse amakhutira ndi khalidwe lathu lodalirika, ntchito zathu zodalirika kwa makasitomala komanso mitengo yopikisana. Cholinga chathu ndi "kupitiriza kupeza kukhulupirika kwanu mwa kupereka khama lathu pakukonza zinthu ndi ntchito zathu nthawi zonse kuti titsimikizire kuti ogwiritsa ntchito athu, makasitomala, antchito, ogulitsa ndi madera apadziko lonse lapansi omwe timagwirizana nawo akukhutitsidwa".

Magawo aukadaulo

| Kulemera Konse (kg) | 2300 | Kukula (mm) | 6000*3500*1600 |

| Kupanikizika Kwambiri kwa Madzi (Mpa) | 31.5 | Mphamvu Yaikulu (kw) | 6 |

| Mphamvu Yotulutsa (kn) | 350 | Silinda yopindika kwambiri (mm) | 250 |

| Kukula Kwambiri kwa Zinthu (Kupindika Kowongoka) | 200*12 mm | Kukula Kwambiri kwa Zinthu (Kupinda Kopingasa) | 120*12 mm |

| Liwiro lalikulu la mutu wopindika (m/mph) | 5 (Mode yachangu)/1.25 (Mode yocheperako) | Ngodya Yopindika Kwambiri (digiri) | 90 |

| Liwiro lalikulu la zinthu zomwe zili mbali imodzi (m/min) | 15 | Stoke of Material lateral block (X Axis) | 2000 |

| Kupindika Moyenera (digiri) | Malipiro agalimoto <±0.5Malipiro amanja <±0.2 | Kupindika kwa mawonekedwe a U (mm) | 40 (Dziwani: chonde funsani kampani yathu ngati mukufuna mtundu wocheperako) |