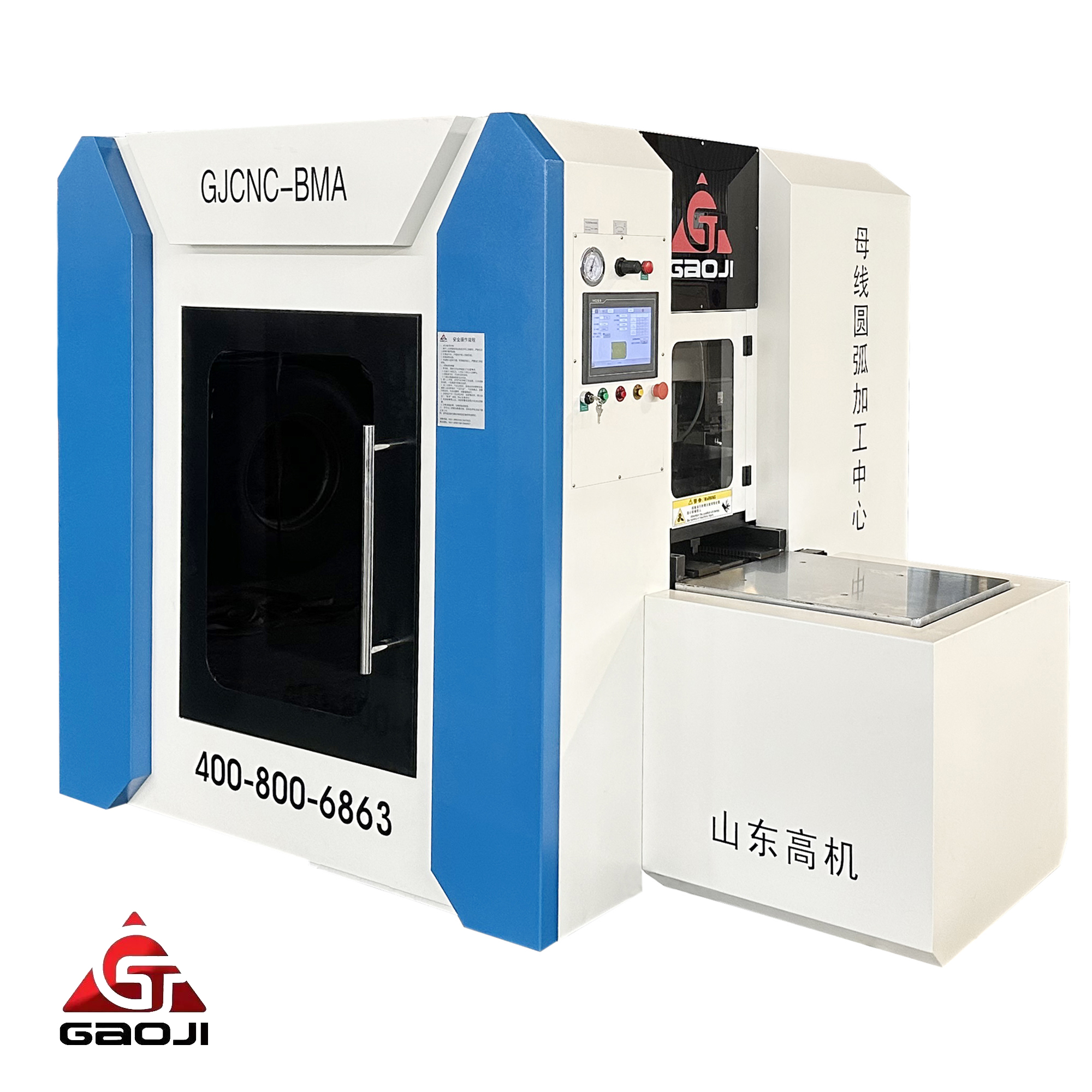

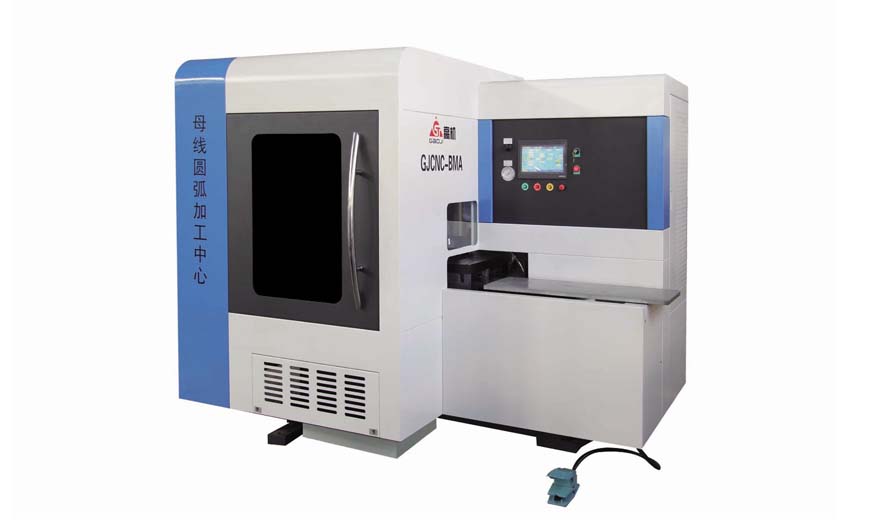

Makina Opangira Mabasi a CNC Copper Busbar Opangidwa ndi Mafakitale Ogulitsa Opangidwa ndi Mafakitale a Switchgear ndi Zipangizo Zamagetsi

Antchito athu kudzera mu maphunziro aukadaulo. Chidziwitso chaukadaulo, luso lamphamvu la kampani, kukwaniritsa zosowa za opereka chithandizo cha makina opangira ma busbar a CNC Copper Busbar opangidwa ndi fakitale opangidwa ndi Switchgear ndi zida zamagetsi, Ubwino wake ndi kukhalapo kwa fakitale, Kuyang'ana kwambiri pa zomwe makasitomala akufuna ndi zomwe zimapangitsa kuti kampani ipulumuke komanso ipite patsogolo, Timakhala oona mtima komanso odzipereka kwambiri, tikufunitsitsa kubwera kwanu!

Antchito athu kudzera mu maphunziro aukadaulo. Chidziwitso chaukadaulo, luso lamphamvu la kampani, kukwaniritsa zosowa za opereka chithandizo kwa makasitomala.Makina Opopera a Busbar a CNC ndi Makina a CNCNgati mukufuna chilichonse mwa zinthu zathu ndi mayankho athu kapena mukufuna kukambirana za oda yanu, onetsetsani kuti mwalankhula nafe. Tikuyembekezera kupanga ubale wabwino ndi makasitomala atsopano padziko lonse lapansi posachedwa.

Tsatanetsatane wa Zamalonda

Makina opukutira busbar a CNC amagwira ntchito makamaka mu fillet yopukutira ndi fillet yayikulu mu busbar. Amapanga pulogalamu yokha ndikutumiza code ku zidazo kutengera zofunikira pa busbar specifications ndi deta yomwe yalowetsedwa pazenera lowonetsera. Ndi yosavuta kugwiritsa ntchito ndipo imatha kupanga busbar arc yothandiza komanso yokongola.

Ubwino

Makinawa amagwiritsidwa ntchito pokonza ma arc a sectional arc heads okhala ndi H≤3-15mm, w≤140mm ndi L≥280mm.

Mutu wa bar udzapangidwa molingana ndi mawonekedwe ake ndi kapangidwe kokhazikika.

Ma clamp amagwiritsa ntchito ukadaulo wokhazikika wokha kuti akanikizire bwino mutu wokankhira pamalo ogwirira mphamvu.

Chowonjezera chimagwiritsidwa ntchito pamutu wokanikiza kuti chikhale cholimba, zomwe zimapangitsa kuti pamwamba pa makina pakhale bwino.

Chogwirizira zida cha BT40 chokhazikika padziko lonse lapansi chimagwiritsidwa ntchito posintha tsamba mosavuta, kulimba pang'ono komanso kulondola kwambiri.

Makinawa amagwiritsa ntchito zomangira za mpira zolondola kwambiri komanso malangizo olunjika. Ma rail akuluakulu olemera asankhidwa kuti apereke kulimba bwino kwa makina onse, kuchepetsa kugwedezeka ndi phokoso, kukonza bwino ntchito ndikuwonetsetsa kuti ntchitoyo ndi yolondola kwambiri.

Pogwiritsa ntchito zigawo za makampani otchuka m'dziko muno komanso padziko lonse lapansi, makinawa amakhala nthawi yayitali ndipo amatha kutsimikizira kuti ndi apamwamba kwambiri.

Pulogalamu yomwe imagwiritsidwa ntchito mu makina awa ndi pulogalamu yojambulira zithunzi yokha yomwe yapangidwa ndi kampani yathu, yomwe imagwira ntchito yodzipangira yokha mu mapulogalamu. Wogwiritsa ntchito safunika kumvetsetsa ma code osiyanasiyana, komanso safunika kudziwa momwe angagwiritsire ntchito malo ochitira makina akale. Wogwiritsa ntchitoyo amangofunika kulowetsa magawo angapo potengera zithunzi, ndipo zidazo zimapanga ma code a makina okha. Zimatenga nthawi yochepa kuposa mapulogalamu amanja ndipo zimachotsa kuthekera kwa cholakwika cha ma code chomwe chimachitika chifukwa cha mapulogalamu amanja.

Busbar yopangidwa mu makina awa ndi yokongola kwambiri, yopanda malo otulutsira madzi, imachepetsa kukula kwa kabati kuti isunge malo ndikuchepetsa kwambiri kugwiritsa ntchito mkuwa.

Antchito athu kudzera mu maphunziro aukadaulo. Chidziwitso chaukadaulo, luso lamphamvu la kampani, kukwaniritsa zosowa za opereka chithandizo cha makina opangira ma busbar a CNC Copper Busbar opangidwa ndi fakitale opangidwa ndi Switchgear ndi zida zamagetsi, Ubwino wake ndi kukhalapo kwa fakitale, Kuyang'ana kwambiri pa zomwe makasitomala akufuna ndi zomwe zimapangitsa kuti kampani ipulumuke komanso ipite patsogolo, Timakhala oona mtima komanso odzipereka kwambiri, tikufunitsitsa kubwera kwanu!

Zogulitsa zotentha zopangidwa ndi fakitaleMakina Opopera a Busbar a CNC ndi Makina a CNCNgati mukufuna chilichonse mwa zinthu zathu ndi mayankho athu kapena mukufuna kukambirana za oda yanu, onetsetsani kuti mwalankhula nafe. Tikuyembekezera kupanga ubale wabwino ndi makasitomala atsopano padziko lonse lapansi posachedwa.

Kapangidwe

| Kukula (mm) | Kulemera (kg) | Kukula kwa Tebulo Logwira Ntchito (mm) | Gwero la Mpweya (Mpa) | Mphamvu Yonse (kw) |

| 2500*2000 | 3300 | 350*900 | 0.5~0.9 | 11.5 |

Magawo aukadaulo

| Mphamvu ya Moter (kw) | 7.5 | Mphamvu ya Servo (kw) | 2*1.3 | Max Torpue (Nm) | 62 |

| Chitsanzo cha Chosungira Zida | BT40 | Chida cha Chida (mm) | 100 | Liwiro la Spindle (RPM) | 1000 |

| Kukula kwa Zinthu (mm) | 30~140 | Utali Wochepa wa Zinthu (mm) | 110 | Kukhuthala kwa Zinthu (mm) | 3~15 |

| X-Axis Stoke (mm) | 250 | Stoke ya Y-Axis (mm) | 350 | Liwiro Lachangu (mm/min) | 1500 |

| Kuponya kwa Ballscrew (mm) | 10 | Kulondola kwa Malo (mm) | 0.03 | Liwiro Lodyetsa (mm/mph) | 1200 |